Return to "Visible Storage"

*** Please note: This website (comp-hist) was completed before I found out about Wikipedia in 2002.

Since then I have added material occasionally.

Items are certainly not complete, and may be inaccurate.

Your information, comments, corrections, etc. are eagerly requested.

Send e-mail to Ed Thelen. Please include the URL under discussion. Thank you ***

magnetic core

Manufacturer - Identification,ID - Date of first manufacture - Number produced - Estimated price or cost - location in museum - donor - Contents of this page:

- Photo

- Placard

- Architecture

- Special Features

- Historical Notes

- This Artifact

- Interesting Web Sites

- Other information

magnetic core

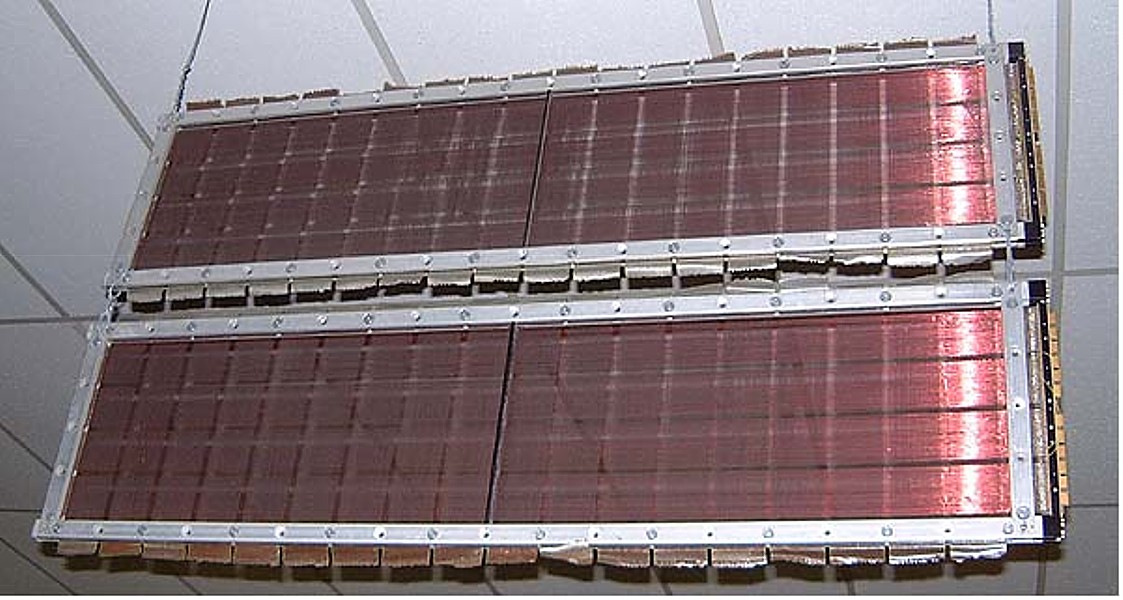

magnetic core - from the Whirlwind computer

-

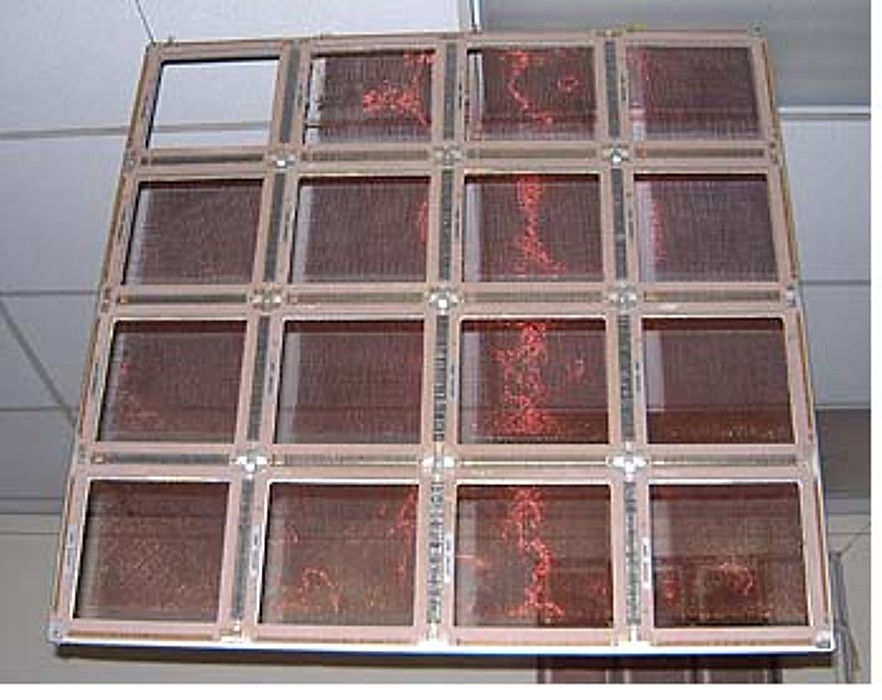

diagram from magnetic core patent

Magnetic Core Memory description from a navy training manual

- Historical Notes

From "Digital at Work" , Digital Press, copyright 1992, page 25

An Innovation in Computer Memory

In the early years of Project Whirlwind, Jay Forrester recognized the limitations of the computer memory systems then available. Electrostatic storage tubes, magnetic drums, tapes, and disks lacked the speed and reliability required for the project. With Forrester's invention of random-access coincident-current core memory, information could be extracted immediately rather than searched for sequentially on tapes or disks. Working with graduate student Bill Papian, Forrester's invention led to an array of ferrite magnetic materials for storing information. In his thesis, entitled "A Coincident-Current Magnetic Memory Unit" (1950), Papian described magnetic core memories, honeycombs of minute magnetic cores strung on wires, through which storage information was read to electronic circuits in the computer. This invention provided the speed and reliability the project required. The first bank of core memory was installed in the Whirlwind on August 8, 1953. Computing speed doubled, and useful operating time increased to more than 90 percent. The same year, Raytheon, Remington Rand, and RCA shifted commercial machine storage emphasis to magnetic core storage, followed a year later by IBM. Although initially unappreciated except by the engineers, scientists, and researchers working on this new technology, its impact on the history of computing would be great. This Artifact

-

From Dr. Mike Williams, Curator of the Computer History Museum

Folks,

While I was away in LA I managed to talk to a man who ran a core memory company. He indicated that there were only a couple of firms that were in the business of suppling OEM core memories and that many many computer companies used these rather than try and make them for themselves.The major players were:

Now if your core plane has TM on it, then I assume that it must be made by Telemeter Magnetics - this might make it easier to find some specs on exactly what currents it takesto drive it etc.

- FABRI-TEK owned by a Mike Nicholson in Minneapolis

- (didn't make cores, but only assembled them) see Note 1 below

- (The founder ... was Mike Mickelson not Nicholson, and more) see Note 2 below

- Telemeter Magnetics (TMI) - later purchased by AMPEX

- (based in LA - both made cores and assembled them)

- General Ceramics (held some of the patents on cores) in N.J.

- Core Memories Limited (CML) in Ireland - an offshoot of DataProducts Ltd

- Electronic Memories Inc. (EMI) an offshoot of Ampex.

Mike Williams

Grant Saviers adds

I think you can add Henry Crouse bought DEC's core memories before he bought RCA. Next time I see him I ask for his list of suppliers.

- Ferroxcube (Saugerties, NY sp?) - OEM supplier of core & planes

- RCA - Waltham, MA or nearby & Taiwan - OEM & RCA supplier of cores and planes

- DEC - bought the RCA core making facility and Taiwan stringing. Only made for DEC

- IBM - only made for IBM

Grant

Note 1

from Rudi Fischer < rudifischer@mchsi.com > May 16, 2012

Ed,

came across your webpage " magnetic cores" and noticed that you did give us at Fabri-Tek some credit with the cores. Yes Mike Nicholson was with Fabri-Tek but we all knew him as the President.On your next line it states that they did not make cores only assembled them. Here is where I can add some insight into Fabri-Tek, Inc. After my discharge in 1968 from the US Air Force I went to work for Fabri-Tek in Fort Washington Industrial Park, Fort Washington, PA. Although I had to start as a janitor, only spot they could create for me, I became Quality Control Manager within six months and yes our product were memory cores.

When I first arrived there we manufactured A5060. "A" being the designation of the first family of cores manufactured by us, the other two numbers were the size and speed of the core. We engineered a "B" version but I don't recall the numbers. Not long after we began the C 3040, smaller and faster. The "D" version never made it past the engineering stage before we managed to produce the E1418.

Because of the poor acceptance rate during production of memory cores, as Quality Control Manager I was allowed to do research of my own and came up with a new way of firing and then cooling the cores which gave us a yield of 80+% compared to under 50% acceptance. The E1418 was the largest number of cores produced by us. As a little background we produced the ferrite powder in-house, pressed the larger cores using old Aspirin presses and finally went to a continues belt press made in France to press the E1418. This pressing procedure increased our production by almost 40%.

Testing came next and all of our test machines were assembled and wired in-house. Cores then came to me and each vial containing 1000 to 2000 cores would be sample on a small hand jig. Depending on the vial size samples were counted and rejects noted and a pass or fail stamp affixed. I would then pack the vials and send them to Hong Kong for stringing.

If there is anything else you may need to know please let me know.

Rudi Fischer

Note 2

from Gale Sorum < gsorum@amerytel.net > - Jan 26, 2018

Ed:

I was a long time employee of Fabri-Tek [07-1963 thru 06-1977] and would like to bring a couple of items to your attention:Gale Sorum

- The founder of the company was Mike Mickelson not Nicholson

- We had a core production facility in the lower level of our facility in Edina, MN and at one point were producing > 100,000,000 20mil cores per week.

- In addition to producing memory cores and stringing core planes [frames], we also produced core memory stacks, and core memory systems.

Amery Wisconsin

If you have comments or suggestions, Send e-mail to Ed Thelen

Go to Antique Computer home page

Go to Visual Storage page

Go to top

Updated Jan 26, 2018