Back to CDC-Experience #GrummanAircraft

Telemetry

in the late 1960s :-))about the time the U.S. did a moon landing

and safe return :-)))

In 2016, I was complaining about Ampex Tape Drives when used for commercial data processing in the early 1960s.

It turns out that both J.P. Moore and Ignacio (Iggy) Menendez had:

- used Ampex tape drives (for telemetry, worked just fine)

- worked at Vandenberg AFB in California

and exchanged experiences and pictures of their time at Vandenberg AFB - "Western Test Range".

| Great Sadness:

I wanted to include a reference to "Telemetry, How does it work" - but there seems no such thing. Even the current (May 2016) article in Wikipedia is useless. After stating that telemetry is getting information from here to there - it just gives a long list of uses - race cars, space vehicles, inside of aircraft or cars, ... now better IRIG STANDARD 106-04 None of the life blood of how telemetry works, data channels, data sampling rates and why, compression yes or no and why, commutation, super-commutation, sub-commutation, ADCs, PAM, PDM, FM-FM, PCM, data synchronization, demultiplexing, system time tags, calibration and conversion to engineering units, ... - very disappointing, no understanding, just fluff. Is our world so busy, trying to learn how to run the 500 apps on our "smart" phones, that there is no time to contemplate how anything really happens? If you can't get it into a seven second sound bite for your seventh grader - just give up ??? |

Some notes from Iggy Menendez

Some notes from J.P. Moore

|

Hey Ignacio,

Good to hear from you. I worked on Minuteman I, I FORCE MOD, II AND III when I was active duty USAF. Stationed at Malmstrom AFB, Montana for 10 years. Very familiar with the damned workcage! We all hated it.....took longer to install then the actual job to be done. I have been known to use a rope ladder to get to the bottom of the silo to change out a sump pump. In and out of the hole in an hour. Timeline called for something like six or seven hours. Had to be certain no QC or other visitors were coming to the site ......rope ladder was for emergency use only. I considered a sump pump change an emergency. JP

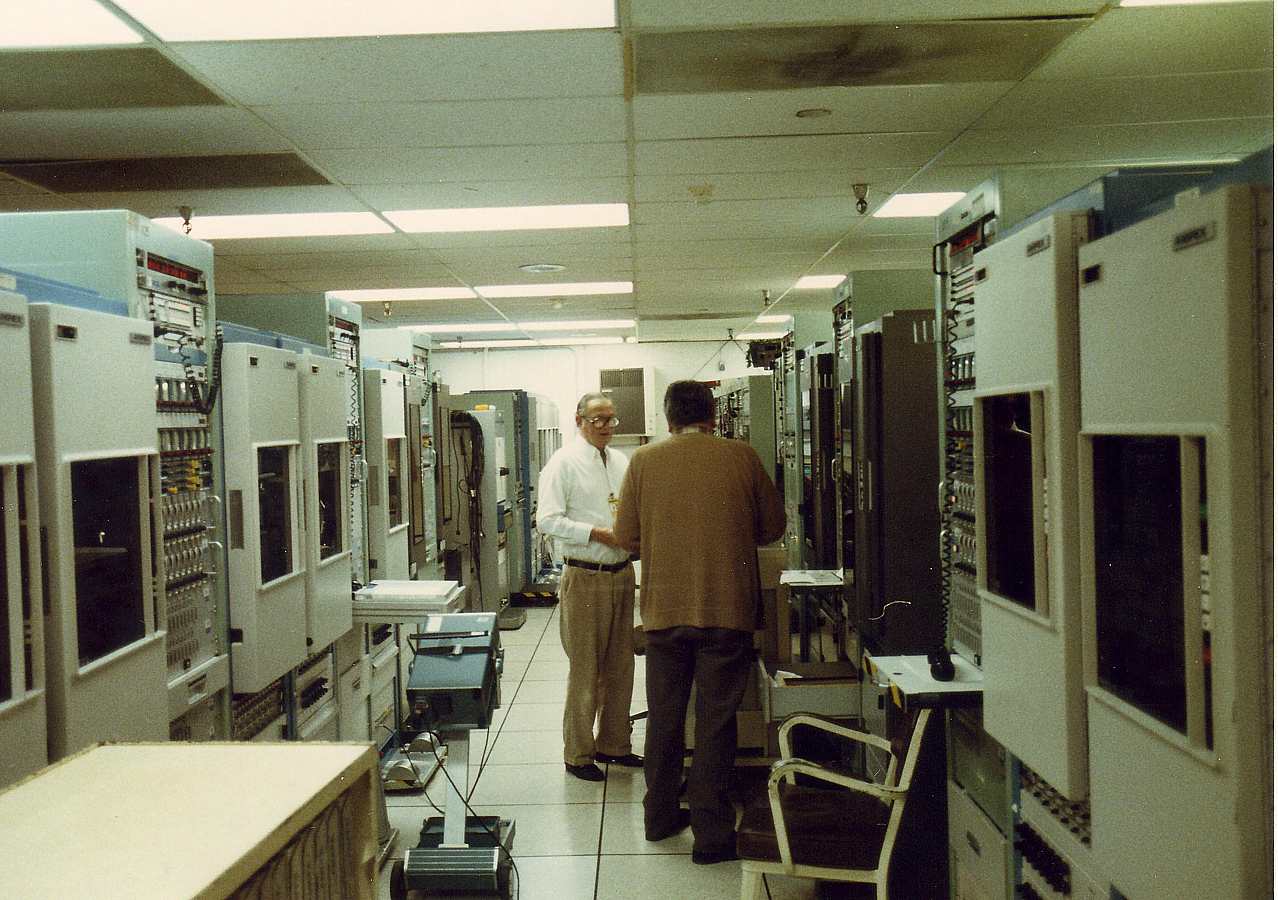

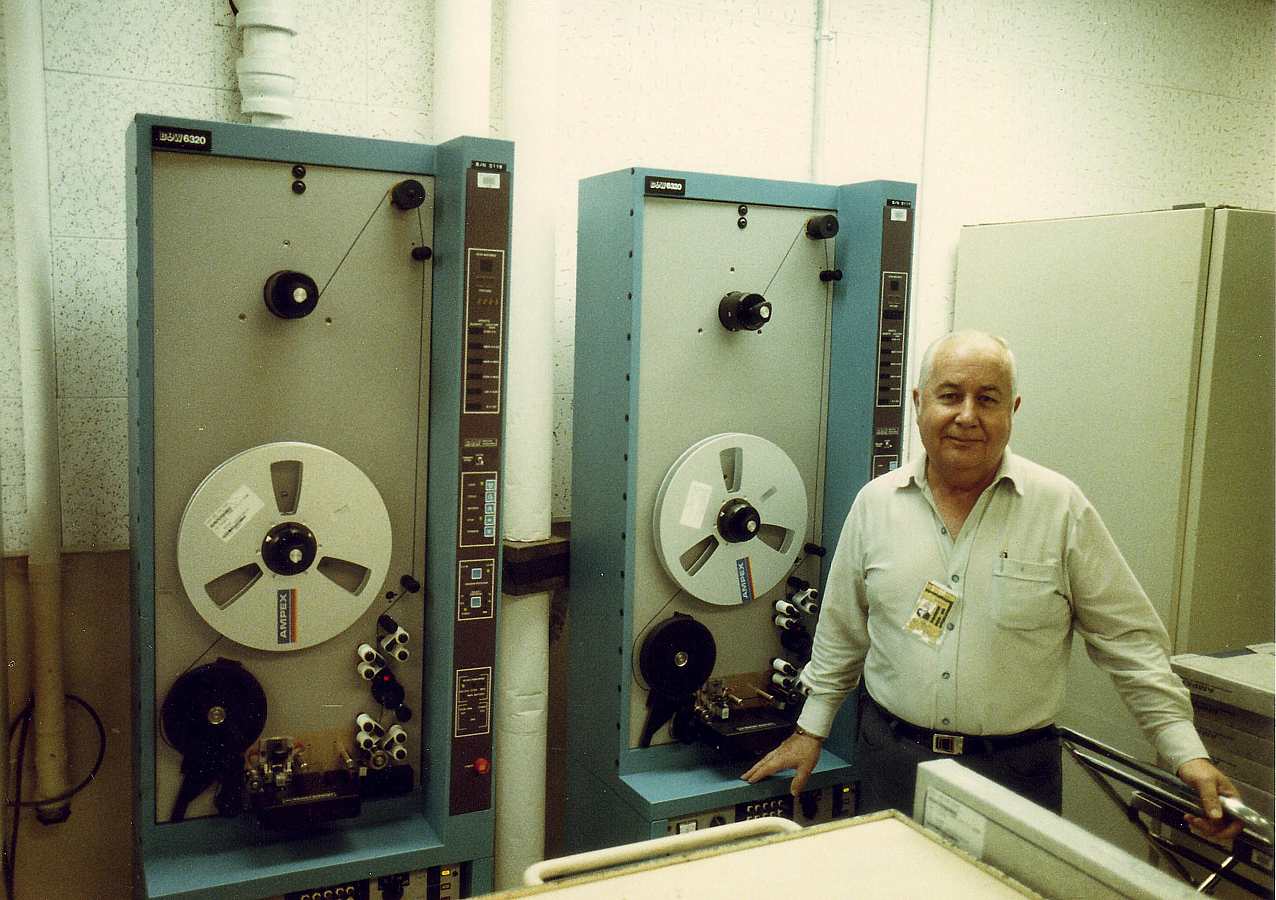

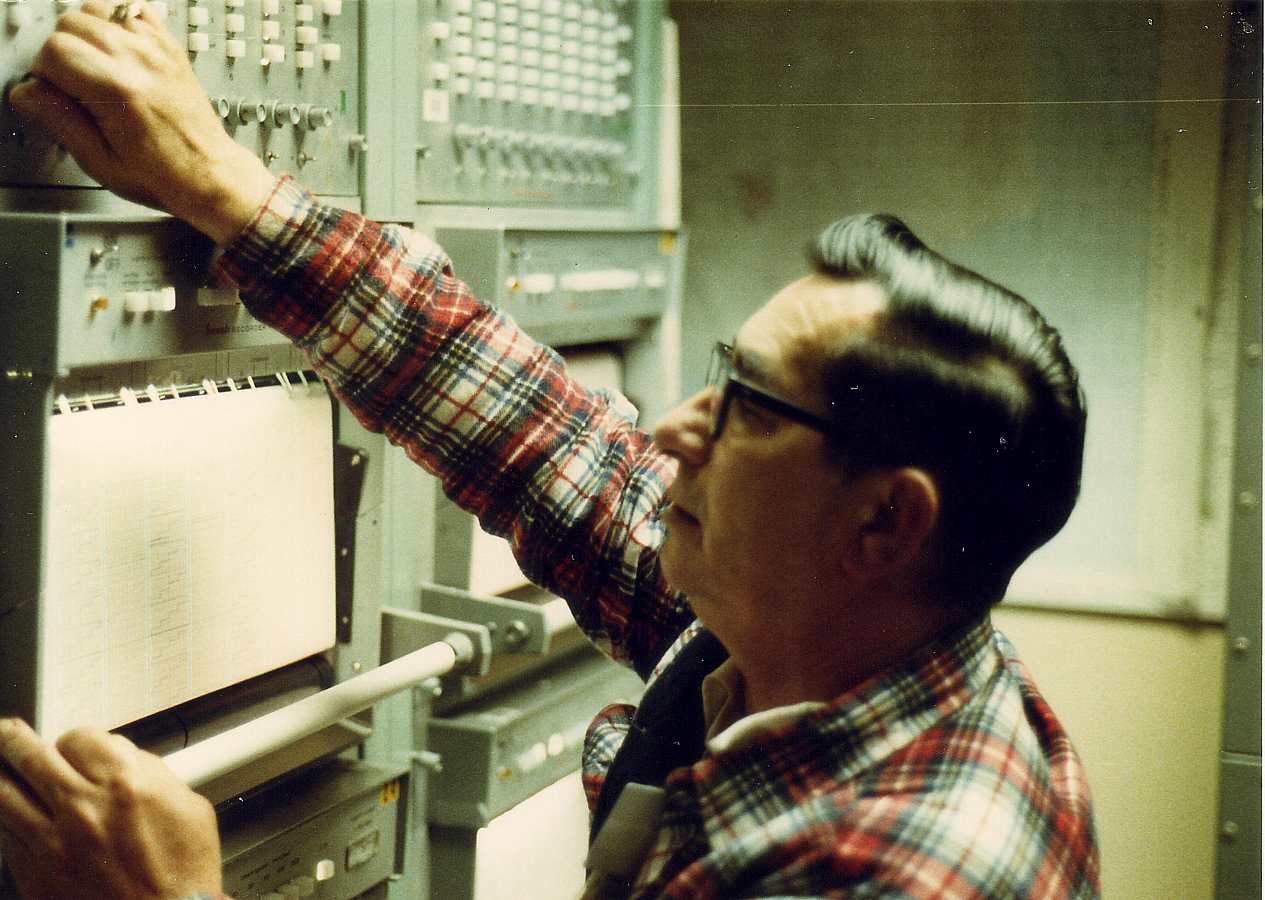

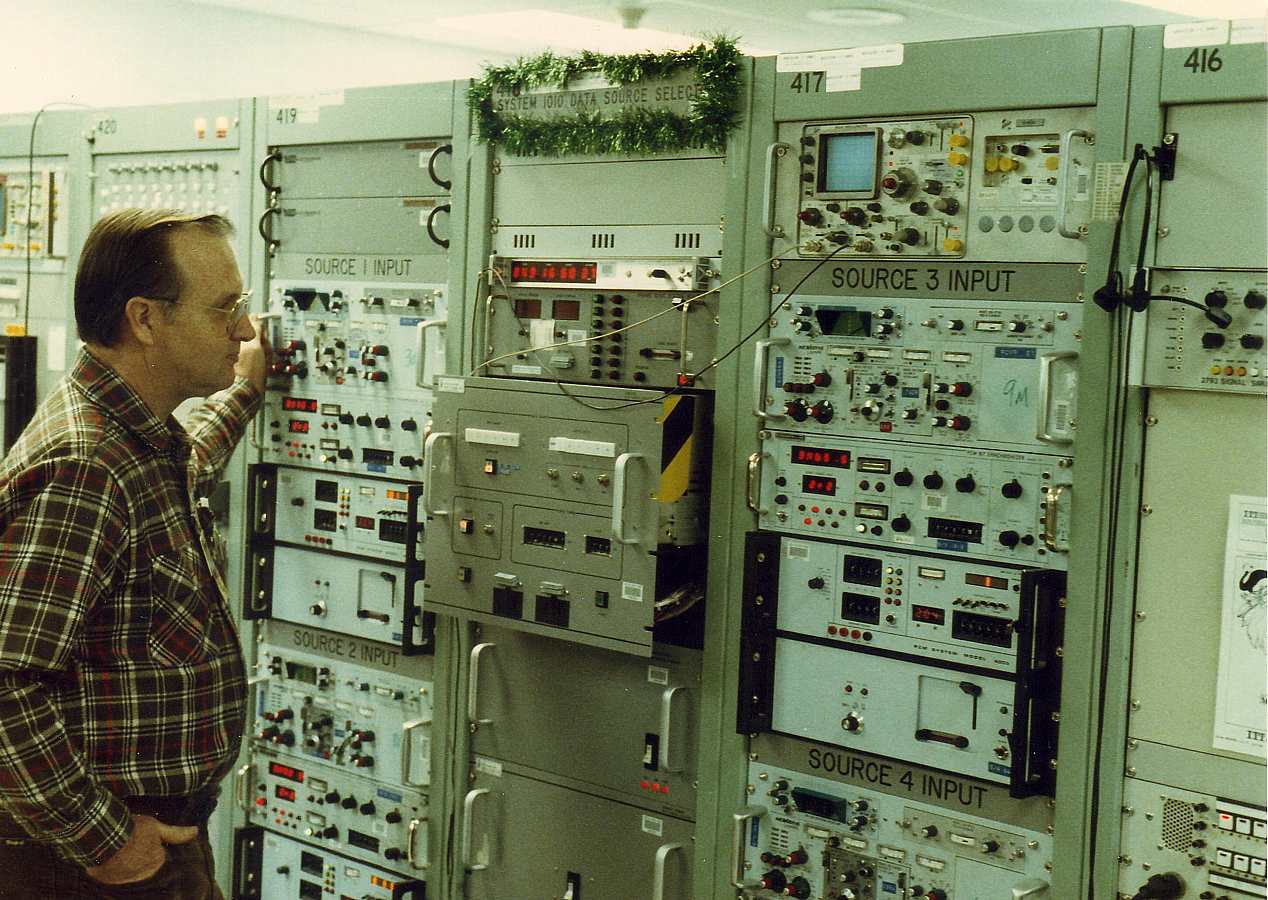

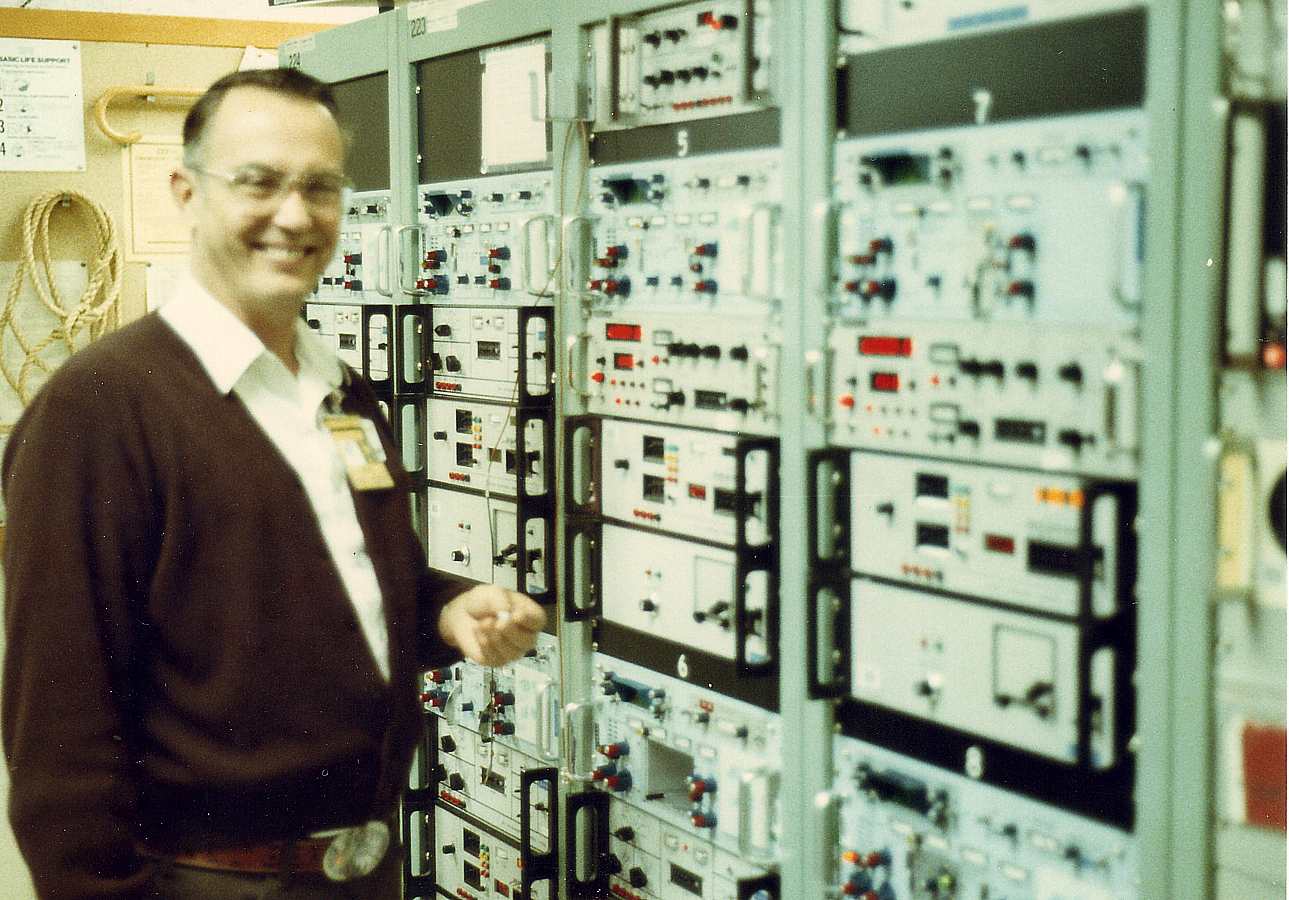

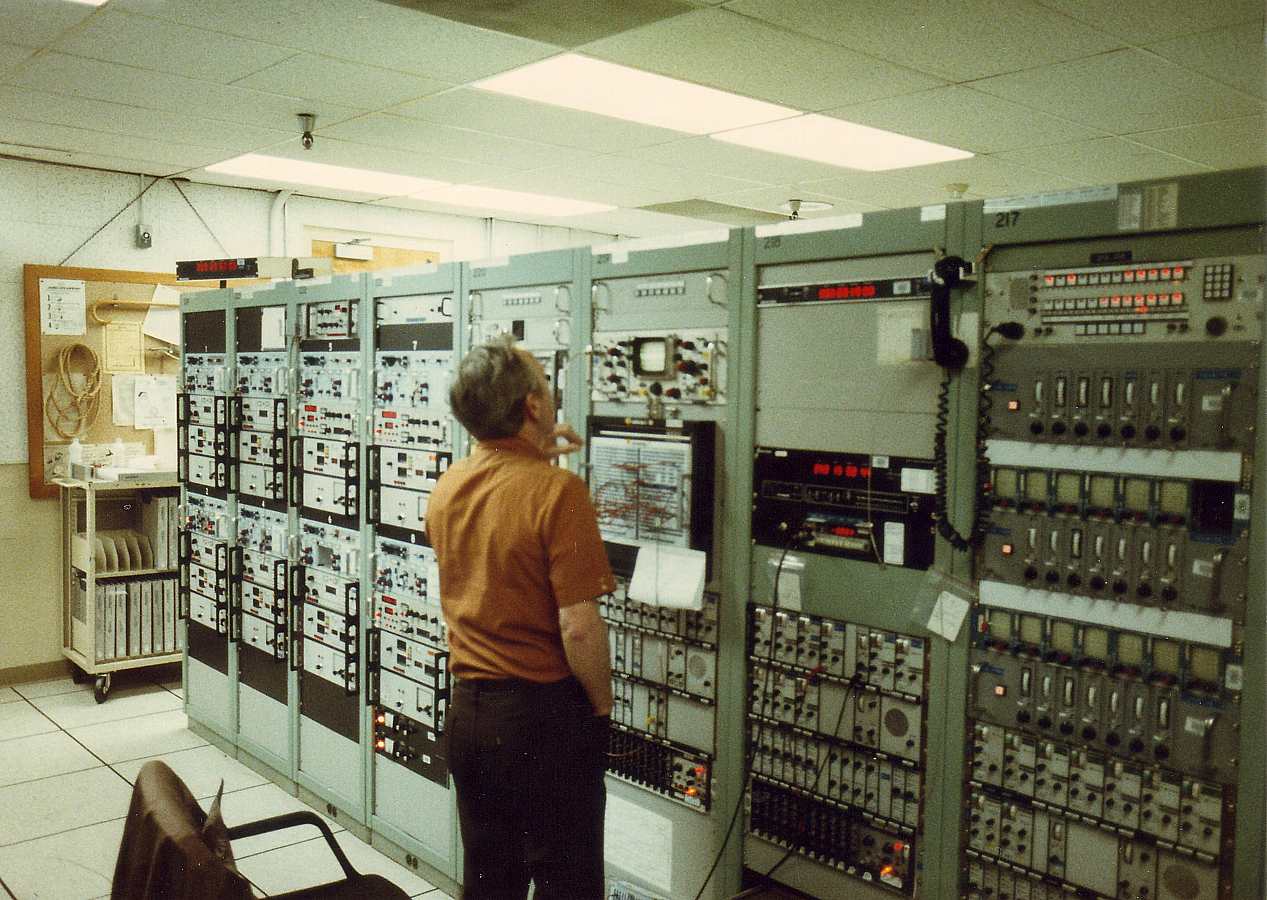

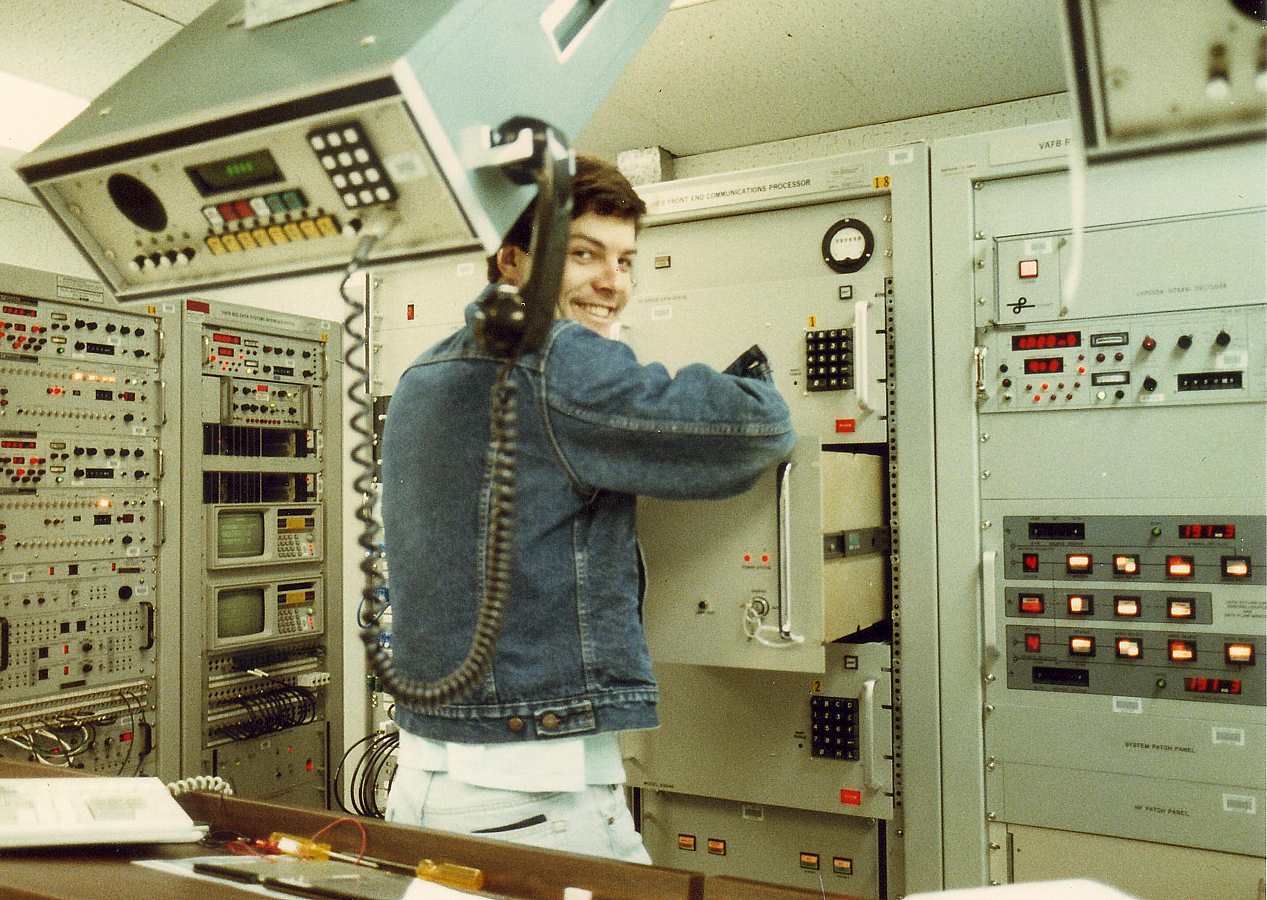

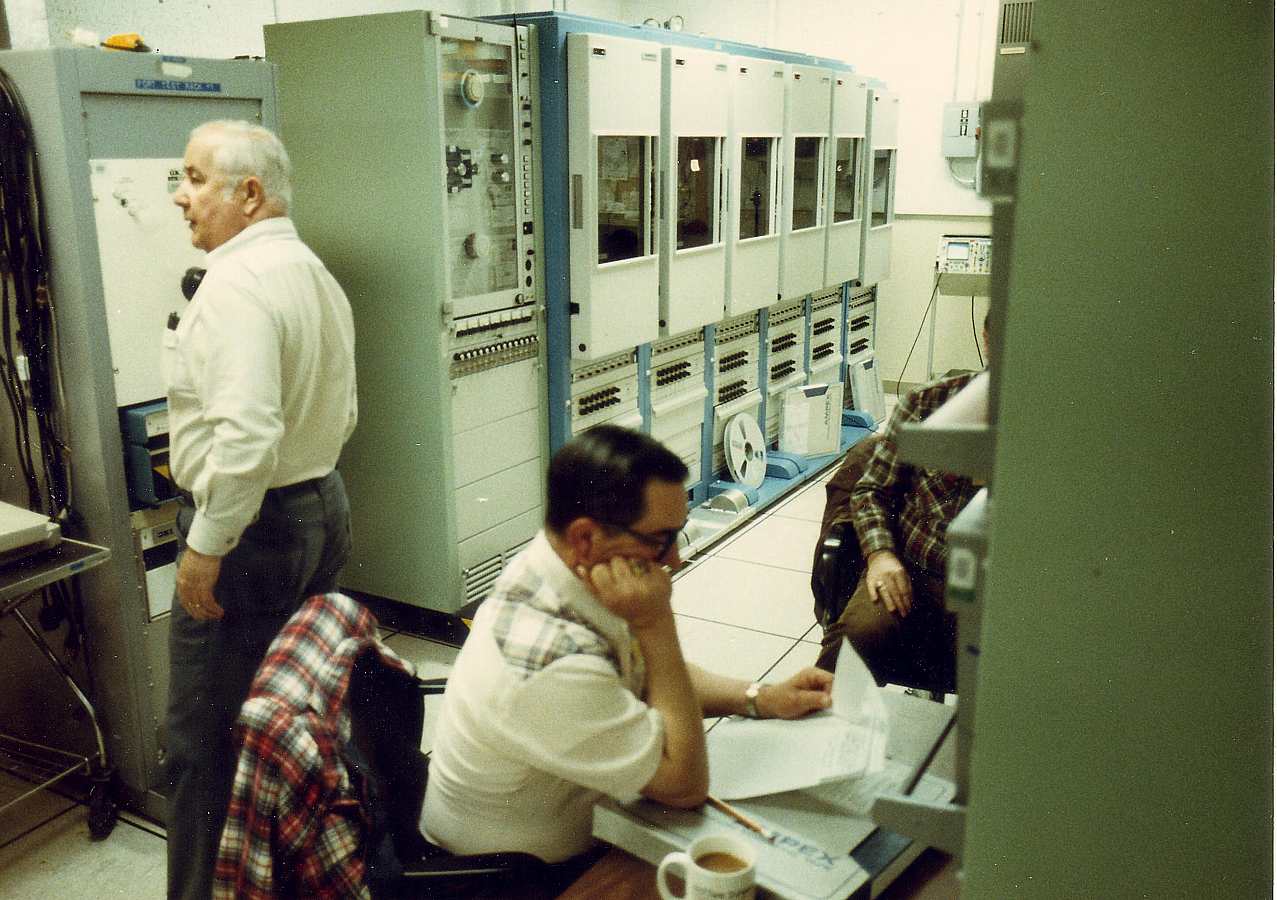

At VAFB, during my time there, Federal Electric Corp was prime contractor for all telemetry. I worked in TAER, (Telemetry Analog Equipment Room) on VAFB roughly 83-89. We had banks of Ampex recorders, and they always worked perfectly. At least I do not remember any problems. Just keep the heads clean and they were good to go. We would receive telemetry from TRS (Telemetry Receiver Site or Station?) which was located several miles from VAFB atop a ridge on a nearby mountain range. TRS had the antennae and receivers and would beam it down to us for processing. TRS recorded the raw signal, I think. We also received signals from the 80' dish at Point Pilar up near Frisco. It came to us via special leased land lines. I think there was an <20 millisecond delay in us receiving it, which we compensated for. First thing we did in TAER was run the signals through a bank of fixed freq. receivers and demuxes and then record it on our Ampexes. We had one man who was a Tape Certifier ....he would run all previously used tapes thru his special machine that erased all data and then checked the tape for drop-outs. The allowable drop-out was a very low number ....if a tape passed the test, we could use it to record on....a tape with too many drop-outs was destroyed. I think there was also a limit to the number of times a tape could be reused. We had 1/2 inch and 1 inch tapes. Somewhere around the house I have pictures of TAER and all its equipment. I'll look for it. JP

It took awhile, but I found some TAER photos made in Dec. 1987. Then I had to fire up the old XP PC to use my scanner. Surprised it still works, has been in the closet for years.

|