BabbageDifference Engine #2 at CHM - Photos

Installation April 9 - 21, 2008

and Maintenance - December 30, 2009

and Move and Repair during CHM renovation - July 2010

"The final demonstration will be January 31, 2016."

Len Shustek introduces Myhrvold & Swade Discuss Babbage's Difference Engine at CHM

"Plan 28 Blog" (project to build a Babbage Analytical Engine)

Winter 2021 report to the Computer Conservation Society

More detailed info on the design and construction of the Difference Engine

Comments:

- This document focuses on the activities of only 5 people who were preparing the Babbage machine for demo at CHM. Many other people planned and did a) the move, b) constructing the environment of two walls and a Victorian Setting, c) electrical and mechanical work, d) and the usual hidden things needed for smooth operations.

- The machine arrived rusty. The engineers were horrified that the polished steel in London,

- now looked similar to the bronze.

- There was a continuing priority struggle for 2 weeks, polish or improve function.

- now looked similar to the bronze.

- The machine arrived with many screws and taper pins loose - and the machine had evidently been dropped or thumped - witness broken counter weight cables, "settled" stereotyping mechanism and column height problems.

- This document is not intended to be comprehensive, just some uncommon views of machinery and people -

- We made liberal use of private 1401 Restoration tools, and CHM tools and facilities to handle the unexpected Babbage machine problems.

Table of Contents

| May 9th, Day 1, arrival

Tightening Steel rusted, looks bronzy Special Tools Carry Problems First OOPS need parts from London Removing a column of carry levers Shifting a rack of arms 0.019 inches | Stereotyping and Proof Printing

End-of-page problem Time's Up, The two weeks allowed are up. Other and Visit Maintenance June 2010, - April 2011 Refurbished Inking Rollers Filming for Docents before shipping to Seattle - Jan 25, 2016 Party Time - I only got the inked printer demo - Jan 25, 2016 |

Principal Actors | (At the end of the last day of a long 2 weeks ;-)) | |||

Doron Swade Started the Babbage "restoration" effort 1989 at Science Museum. list of videos. ... history ... video ) |  Richard Horton Helped Reg Crick build 1st machine. Engineer in charge of building this machine. |  John Shulver Filled in for technician. Engineer in charge of steam engines at Science Museum |  Tim Robinson Made Babbage Engines from Meccano parts - see here and here. Heads docent Babbage training effort. |  Judith Haemmerle CHM Volunteer, mechanical enthusiast. |

Babbage Arrival | Richard Horton and John Shulver arrived from Science Museum to install it. | |||

We are all waiting | Tim Robinson showing Richand (left) and John Shulver (center) a portion of Tim's approximation of Babbage Analytical Engine |  Tim showing Card Reader |  At last ... |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reporters |  Removing Bracing |

| ||

Tightening | ||||

| Many screws & taper pins loose, some fell out - Tim spent hours checking and tightening. |  | This pin had fallen into the oil drip tray below. |  | |

These situations required machine rotation or parts removal to check/tighten. |

|

|

|

|

Steel rusted, | ||||

The "bronze" on top is steel. You can see some protected steel inside. |  Three containers of BRASSO, emery cloth, and abrasive rubber pads were used to remove rust. |  Tim working on the stereotyping engine. Maybe 80 people hours of polishing? |  Tim and Judith polishing, John is probably polishing also - |  Judith adding BRASSO to her polishing rag. |

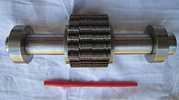

Special Tools | ||||

| The "L" shaped steel tool in the center adjusts the carry arms.

|

| This unusual screwdriver is shaped to fit screw heads perfectly and leave fewer marks and burrs. |

|

| This "FoodLube" smells better than the oil used in London :-)) |

| And a neutral smelling grease ;-)) |

|

Carry Problems | ||||

Tim provided a list of what each column of 31 figure wheels should contain each cycle | - to localize missed or extra carries

The circled items indicated a missed carry in "D3", a really trouble column.

|  Doron explaining the carry system to Al Kossow (bitsavers.org) | Note the carry lever bending tool near Doron's left hand. This tool helps correct local missed carries and false carries. |  Richard Horton bending part of the cast bronze carry lever - a few thousandths? |

First OOPS | ||||

| Confusion while adjusting the "D3" axis left some carry levers set when the crank was turned during part of the set-up. This breaks carry levers. | Emergency call to Science Museum (London) yields box of replacement carry levers. |

|

| |

Removing a column of carry levers | ||||

| Column removal and replacement is a one to two day adventure :-(( |

| Marking the layout table to organize parts for replacement in the same relative location. |

| |

|

|

|

|

|

|

|

|

|

|

|

|  Very snug fit, no slop |  A little help | During the reassembly process, Richard polished, lubricated, and checked smooth operation of all parts going onto the third difference shaft - several hours of meticulous work. |

|

|

|

|

|

0.019 inches | Shifting a rack of arms 0.019 inches | |||

| Game plan: use double shims totaling 1.019 inches. Actually needed double sided tape to secure during installation. |  John making holes with little burring |

|

|

|

Stereotyping | ||||

Wooden handles help wind up weights during debug |  Control lugs of 30 individual impression wheels |  Characters to make impressions in stereotype media |  |  |

Spools for paper for proofing |  The "jaws" facing inwards lock the impression wheels while being lowered toward the stereotyping plate |  note brass screw and nut to hold alignment during insertion. |  Another view of locking jaws |  A complete assembly |

End-of-page problem | ||||

| About 2 hours before leaving Monday for the Going Away Party, and engineers back to London - | an impossible problem came up. The control for the clutch stopping operations at end-of-page failed | Every thing seemed correct - but it would disconnect at strange times - Maybe we are suffering from battle fatigue? |

|

|

Time's Up,The two weeks allowed are up. | ||||

| We then wrapped the machine because the wall would be sanded tomorrow.

- Right, Many Thanks Good Bye Party |

|

|

|

Other | ||||

|  Babbage School |  Tim Robinson instructing | ||

Visit | ||||

Visitor's 1st view Movies in black TV on right |

<- analytical="" engine=""> -> Difference Equations |

Judith and John Apron means docent | The Engine is scheduled to be at CHM until -

UPDATE - Nathan Myhvold has extended to loan to December 2009 :-)) - then off to his living room, with the tyrannosaurus rex. |

Maintenance - December 30, 2009

Sorry this is so short - I was in a hurry to go elsewhere when :- Tim Robinson (our master Babbage Engine Mechanic) had just returned from England (his home land) and while there had consulted with Richard Horton (the builder of this edition of the Engine) about problems with this engine. (apparently carry levers are breaking at a greater than expected rate).

- They compared timings, decided that the carry timing on this machine was different (and not correct) compared with the original Engine at the [British] Science Museum.

- When the CHM Engine is moved to another location, as part of the complete reorganization and re-curration of CHM, Richard Horton will come to CHM and do a major rebuild of the carry section - including the replacing carry levers currently broken.

- This type of operation is shown here

- Randy mentioned that this month PBS had carried an interview with Tim Robinson about the machine, and the next Wednesday about 150 guests tried to crowd into the 2:00 P.M. Babbage Engine demo -

Move and Repair during CHM renovation - July 2010

|

July 2010 - the 2nd Babbage machine was moved to another location in CHM

to make way for a major museum internal rebuild to support the new desplays and organization.

(The new Grand Opening should be late in the fall of 2010.

These pictures are from Herb Kamer, on Flickr After the move, the machine is partially disassembled to insert new carry levers which were broken over the past 2 years. The reason for the breakage in now understood and corrected :-)) The operations are very similar to those previously in Removing A Column Of Carry Levers above. |

Babbage down for a few weeks - April 2011

|

This is a report from Jim Strickland's CHM "Volunteer Information Exchange", Volume 1 Number 7, May 16, 2011.

(CHM regards most of the contents private.) |

|

Starting | Starting - before 8:30 ;-((

Director Plutte bending over table, Tim Robinson (red shirt) as the solo actor. |  Discussing 1st Scene | Director Plutte and Actor Tim Robinson discussing 1st scene. |

Tim Cam Stack | Tim pointing to and explaining the Cam Stack. We see the "Steady Cam" in use. Lowell Klaisner is polishing (off camera) |  Lisa Robinson | Lisa Robinson is a volunteer helper (and machine polisher and makeup artist) |

Lowell Klaisner | Lowell Klaisner is a volunteer helper (and machine polisher) |  Lisa doing hair | Lisa Robinson tidying up Tim Robinson's hair |

Tilted Table | The table was level for the first shot, but now tilted for the second shot and better view. |  Director Plutte | Director Plutte and assistant checking progress. |

Adder Parts | Tim demonstrated how these interacted, moving up and down under control of the cam stack. |  Print Faces&Gears | The narrower set prints with ink on paper for monitoring progress. The wider makes impressions in (like plaster of paris) for making tables. |

Noise | The building was rented by a group matching genetics to medical treatments. The room above had one of the presentations. The noise in this echo chamber was very fatiguing !! |  Printer | By about 4:30, the printer was the last topic. |

Party Time - I only got the inked printer demo - Jan 25, 2016

| However, Marc Verdiell posted a

YouTube

of the Babbage machine at the going away party,

and I get my millisecond of fame (2 minutes and 50 seconds in) ;-)) |

Other Info

- a fun (New Yorker) article about Nathan Myhrvold, who funded and owns this machine. Wouldn't it be nice to imagine "the rest of us" could handle serious money in such a fun useful way? - link from Roy Ogus - Local copy

- a current Myhrvold interest

- A 2007 visit by Nathan Myhrvold to CHM

- How to calculate the eight Babbage Difference Engine #2 parameters for arbitrary functions and other Engine info -